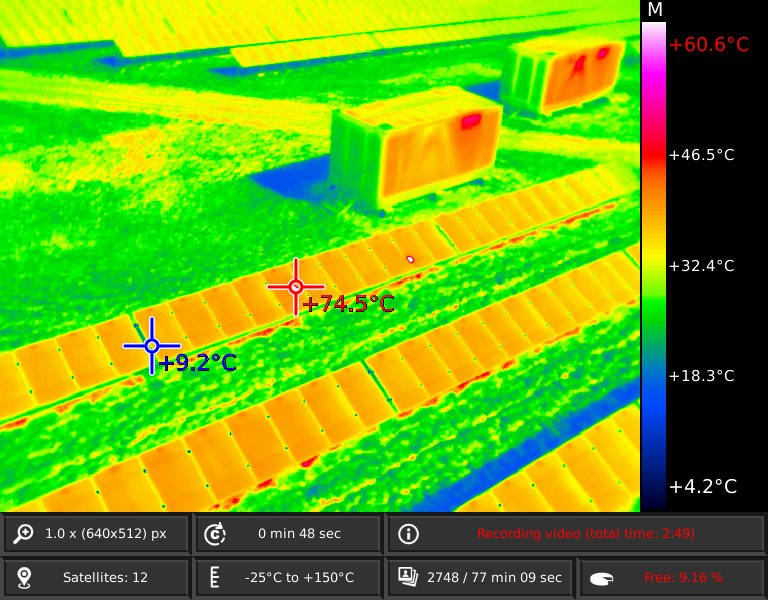

Drone Thermography

Process defects are defects caused by poor construction and incorrect panel use. For the user, this may include mechanical damage from careless use (scratched, cracked or broken cells), or the insufficient maintenance of surface areas, which can lead to dirt settling over the photovoltaic surface. Dirt can compromise the integrity of individual layers of the panel caused through dispersion into the silicon material during the manufacturing process. Most of the aforementioned defects result in the occurrence of hot places, known as hot spots. These occur when there is an increased recombination of electrons. Energy released during this process is radiated into space as heat. This excessive heating can lead to a thermal differential of more than 50°C when compared to normal cells.

This often leads to irreversible damage to the defective cell, as well as to the whole panel. Yet inspection of individual photo voltaic cells is usually a difficult task. Either the panels are located high up on the roofs of buildings, or the area of the solar array is large, and a visual inspection is both time-consuming and financially demanding. However, the omission of regular inspections once a year can have fatal consequences in the form of fire.

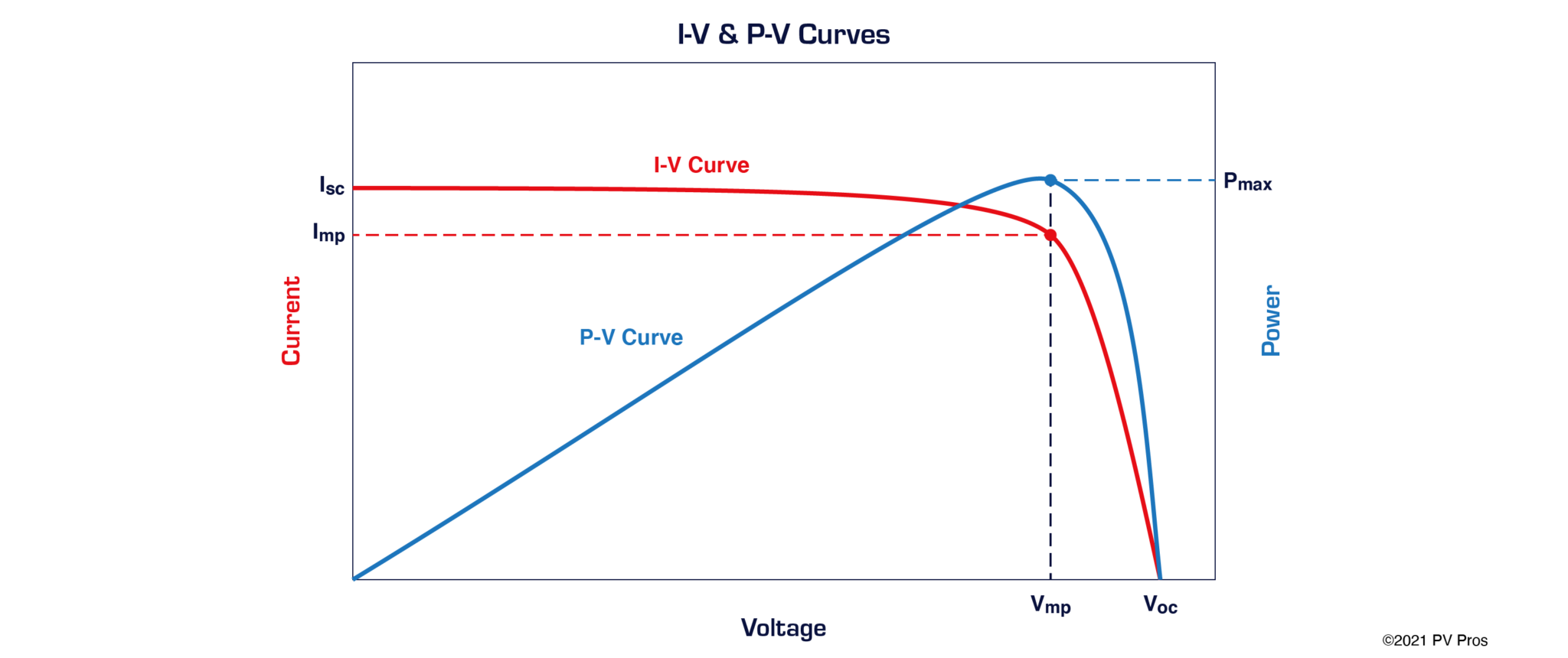

String IV curve tracing activity

An I-V curve tracer works by sweeping a load across the operating range of a PV power source. The tool simultaneously measures the output current and voltage at different points across the operating range of the source circuit or module. By capturing a representative set of operating points between Isc and Voc, the tool is effectively able to outline or trace the entire I-V curve.

EL Testing